Services

Services

Services

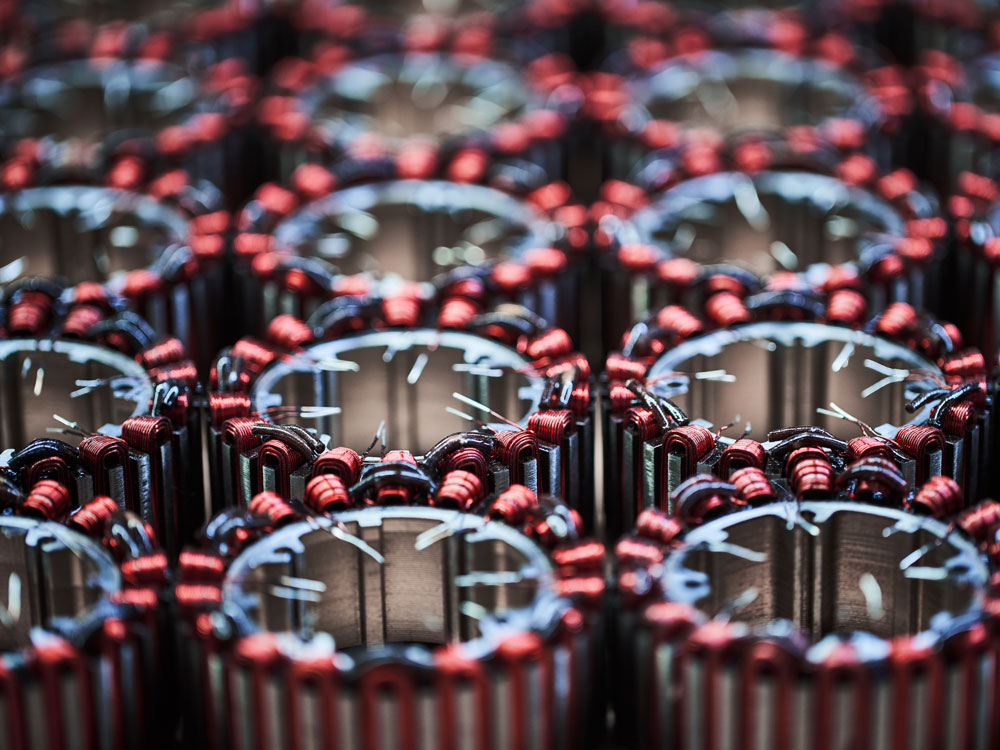

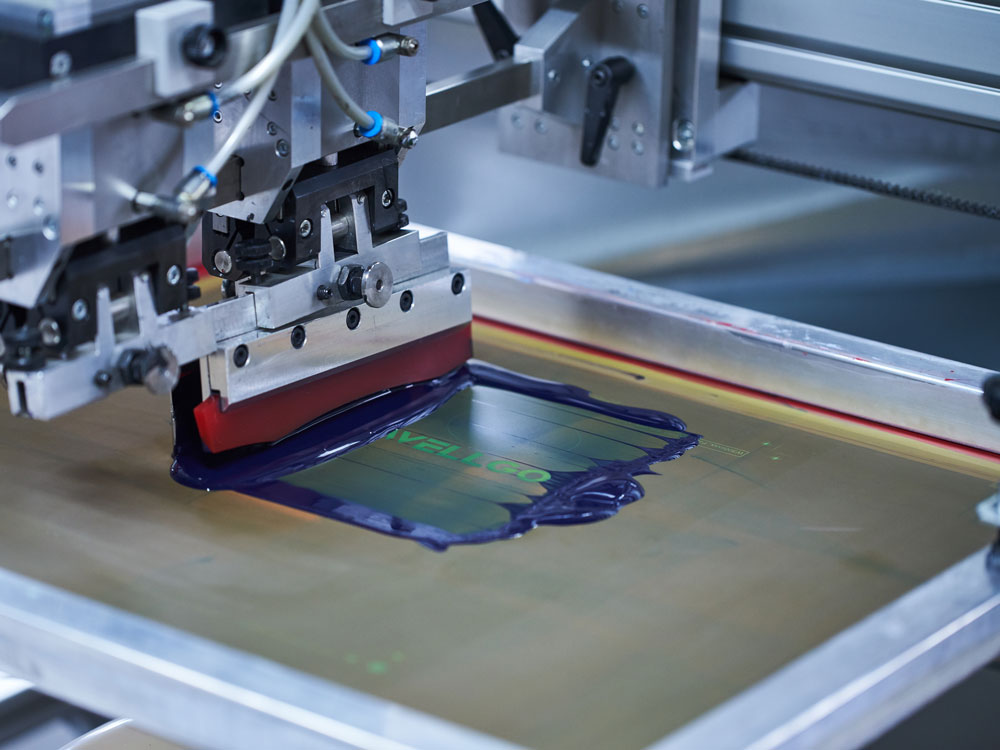

For the automotive industry, the WELLGO Group manufactures carrier parts, functional parts and more sophisticated painted and unpainted visible parts for exterior applications. In the field of e-mobility, electric motors are manufactured. In combination with a sensor handle developed in-house, these can be used in various products to intuitively support people in everyday life. In addition, the WELLGO Group develops and manufactures electrical plugs and cable harnesses for this industry. In the hygiene sector, the WELLGO Group manufactures automatic touch-free towel dispensers, soap and soap foam dispensers, hand sanitisers and fragrance dispensers completely in-house.

A reliable cooperation partner

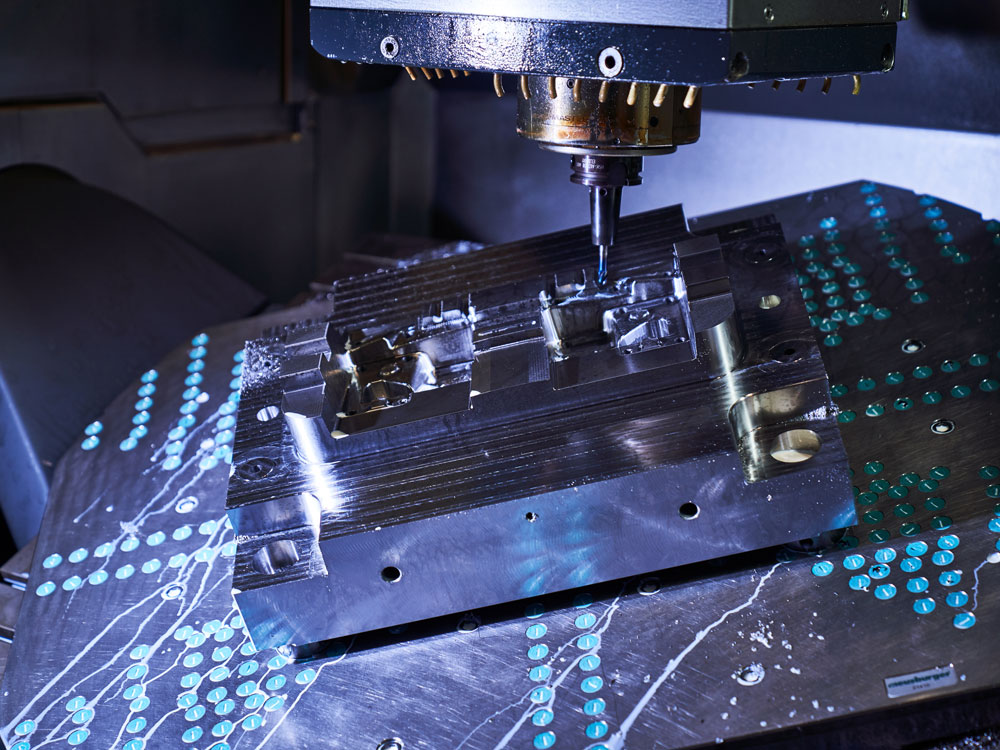

We design and manufacture plastic injection moulding tools in our in-house toolmaking department and also produce your plastic component in series. Smaller and larger component assemblies can also be performed. The WELLGO Group’s wide-ranging level of expertise enables it to provide its customers with advice in many areas. The WELLGO Group is therefore a reliable cooperation partner.