Tool Shop

Tool Shop

Individually manufactured injection moulding tools

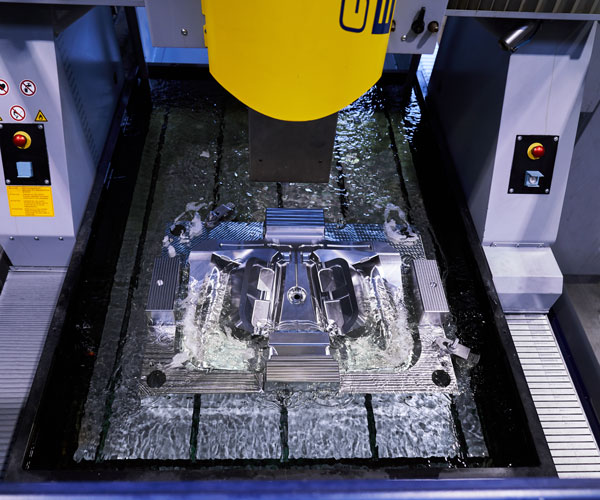

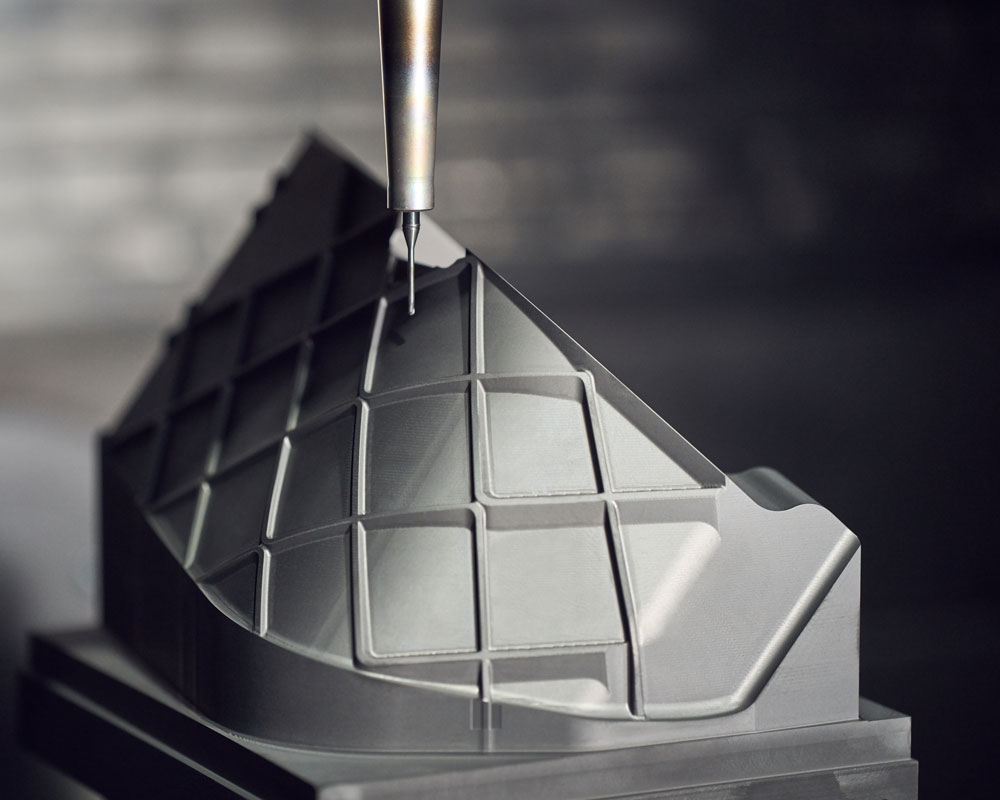

The designers of the WELLGO Group develop injection moulds for plastic components according to customer requirements. The plastic-compatible design of the injection moulding tool plays a major role in this. The positioning of the sliders, ejectors, cooling and sprue channels as well as the injection position are determined here. These factors influence the quality of the finished plastic part. The many years of experience of the WELLGO Group in combination with the use of state-of-the-art technologies lead to high-quality injection moulds.

We rely on the latest technologies

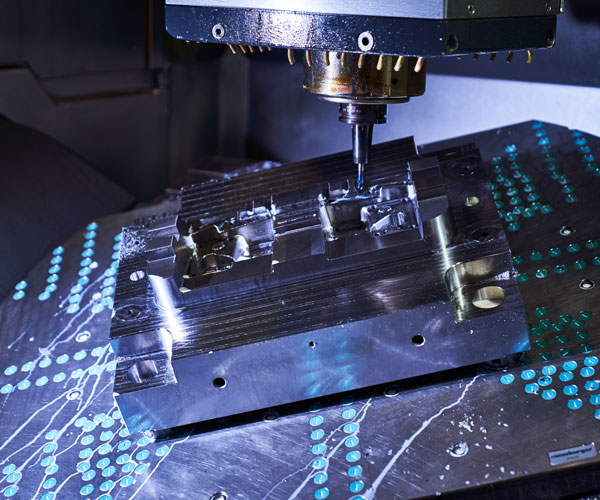

The department’s current achievement includes a fully automatic Mold Center from OPS Ingersoll, which combines the two technologies of high-speed milling and spark erosion and thus significantly reduces throughput times. The electrodes required for an injection moulding tool are milled from graphite and transferred fully automatically directly to the spark erosion machine.

Injection moulding tools made in Germany

WELLGO - Machine park at a glance

With its state-of-the-art machinery, which includes three 5-axis milling machines and several 3-axis milling machines, the WELLGO Group is able to manufacture complex injection moulding tools on schedule. The tool shop produces more than 140 tools a year, which means that on average one injection mould is completed every other day. The broadly diversified installation enables a high degree of flexibility and allows even short-term change requests to be implemented quickly.