Injection Moulding

Injection Moulding

Injection Moulding

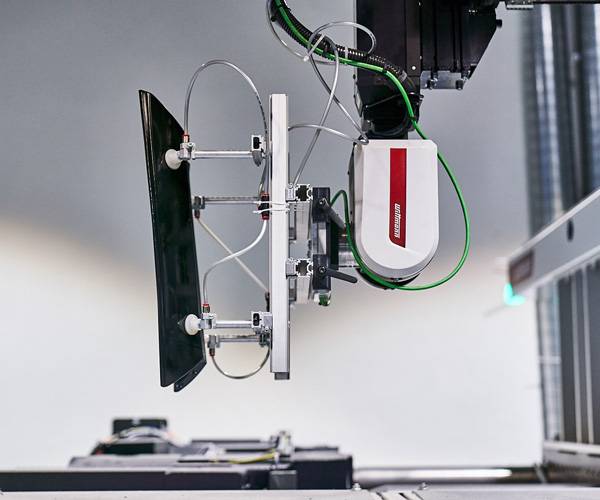

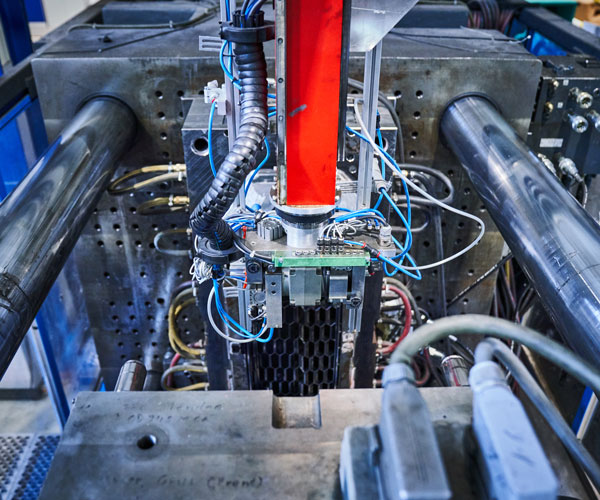

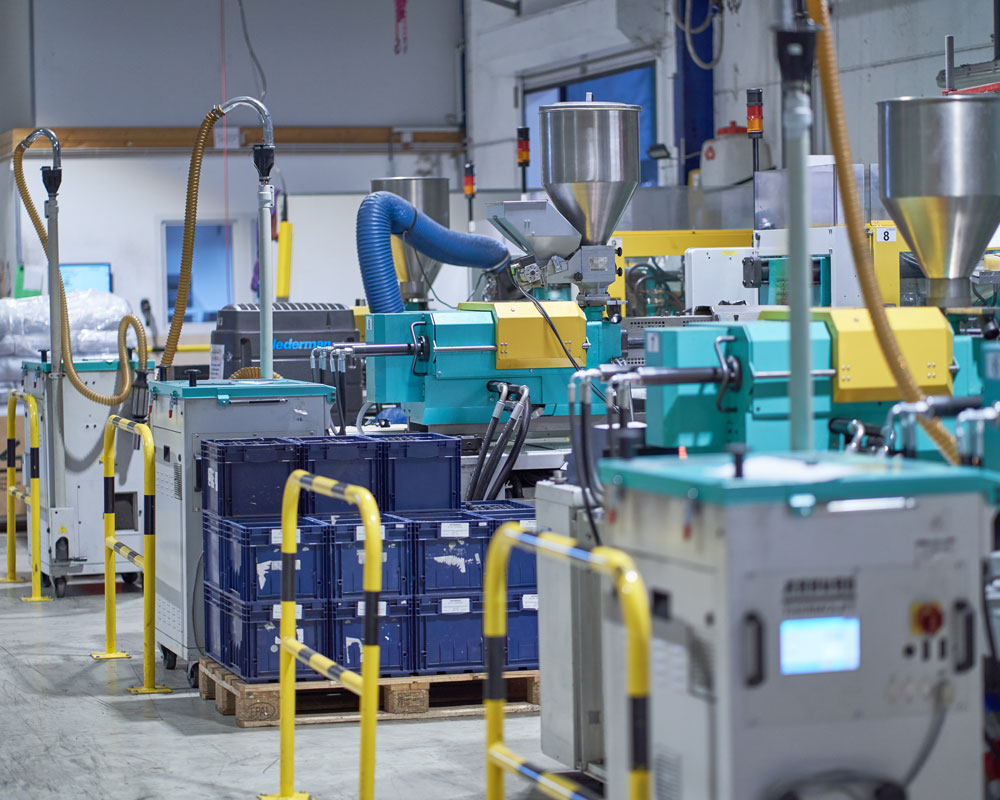

The WELLGO Group currently has 44 injection moulding machines with locking forces from 400 kN to 9900 kN at its disposal. Over 200 different plastics are processed. Production takes place in the immediate vicinity of the tool shop, so that direct communication takes place between the specialists of both departments due to the short distances.

Injection moulding and toolmaking perfectly matched to each other

The interdisciplinary exchange between the two areas results in very high quality since injection moulding and tool making can be perfectly coordinated.

Minimizing costs through expert knowledge

Optimizations will be carried out directly on site, minimizing set-up times and costs as well as transaction costs. This association of the expert knowledge of the WELLGO Group promotes the production-oriented design of plastic components and ensures perfect compatibility with the interfaces of other components.