Quality

Quality management at the highest level

Quality management at the highest level

The quality management of the WELLGO Group is involved from day 1 of the product development process, so that process sequences can be designed with the highest quality. Various variants of quality control can be carried out.

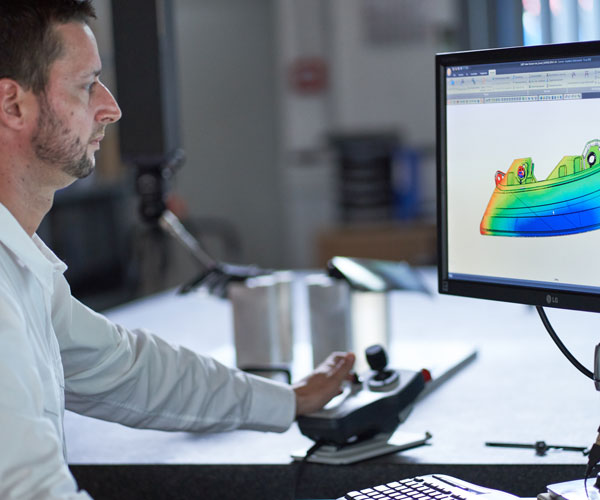

KMG based 3D laser scanning method

The WELLGO Group uses the Wenzel LH 1210 measuring machine in an air-conditioned measuring room to check the products. It has a maximum travel distance of 1200 mm in the X direction, 2000 mm in the Y direction and 1000 mm in the Z direction with a load capacity of 3 t. In addition to a probe head with the touch needle sizes 5 mm, 3 mm and 1 mm, it is equipped with the KMG-based 3D laser scanner L100 from nikon.

DIN EN ISO 9001:2015 TÜV certified

The quality management system is certified according to the latest standard DIN EN ISO 9001:2015 by TÜV Saar. Initial sample test reports are prepared using PPAP procedures. Entering the products into the IMDS database is not a problem.