History

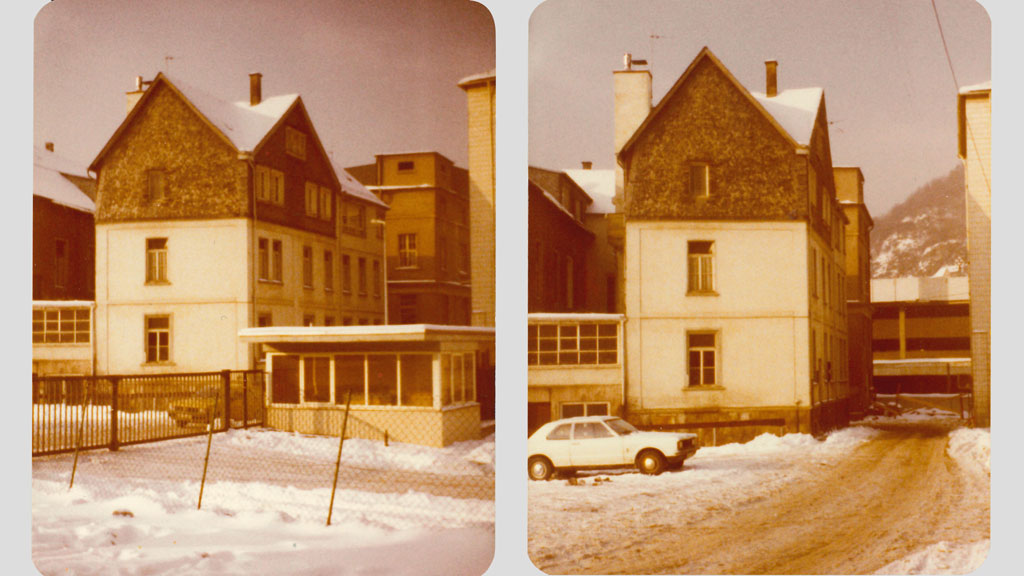

1982

In 1982 Heinz-Jürgen Wermke, Manfred Linn, Albert Loch and Peter Griebel joined forces and founded WELLGO GmbH in Idar-Oberstein. The aim of the company was the production of injection moulds and plastic injection moulded parts. Mehr...

1986

The expansion of the machine park meant that the production area of 250 m² was no longer sufficient. Therefore WELLGO decided to relocate in spring 1986. A suitable industrial hall with an area of 750 m² was found in Nohfelden Mehr...

1989

At the end of 1988 the extension of a new production hall was started, which extended the production area to 1,400 m². At this time the number of employees was already twelve. With the completion of the extension in spring 1989, the machine park Mehr...

1993

In 1993 the extension of a further hall was started, which extended the production area to a total of 2,000 m². In the same year the company moved Mehr...

1997

The machine park was constantly expanded and in 1997 already comprised 25 injection moulding machines, 10 tooling machines and 2 spark erosion machines. Every year WELLGO processed approx. 250 tons of plastics from more than 35 different types of plastics. The main focus of the product range Mehr...

2006

The shareholders of WELLGO GmbH decided to separate the two plants organizationally. In the course of this, WELLGO GmbH was renamed WELLGO Werkzeugbau und Spritzgussteile GmbH and WELLGO Gerätetechnik GmbH was founded. From this point on, WELLGO Gerätetechnik Mehr...

2008

The production area was extended in 2008 by the construction of a new hall with an area of 600 m². In this hall the tool shop Mehr...

2016

With the ever-increasing number of injection moulds produced, the storage area was expanded to include an air-conditioned 450 m² tool storage hall. In addition, the company location was enlarged by a third plant in the industrial area of Otzenhausen. The buildings Mehr...

2017

WELLGO Systems GmbH, the newest company in the WELLGO Group, was founded in 2017 for the development, production and sale of drive technology. In addition, the storage area of Plant II Mehr...

2018

In order to close the production gap between the injection moulding machines with a clamping force of 5000 kN and 10000 kN, an injection moulding machine from ENGEL with a clamping force of 8000 kN and another injection moulding machine from Engel Mehr...